Vision Inspection Systems Development & Integration

AIP specializes in Vision Inspection Systems Development & Integration, delivering intelligent automation solutions that transform quality control into a fully automated, data-driven manufacturing process. Our advanced vision inspection solutions combine high-resolution industrial imaging, AI-based defect detection, and real-time processing algorithms to ensure consistent product quality, precision verification, and production reliability.

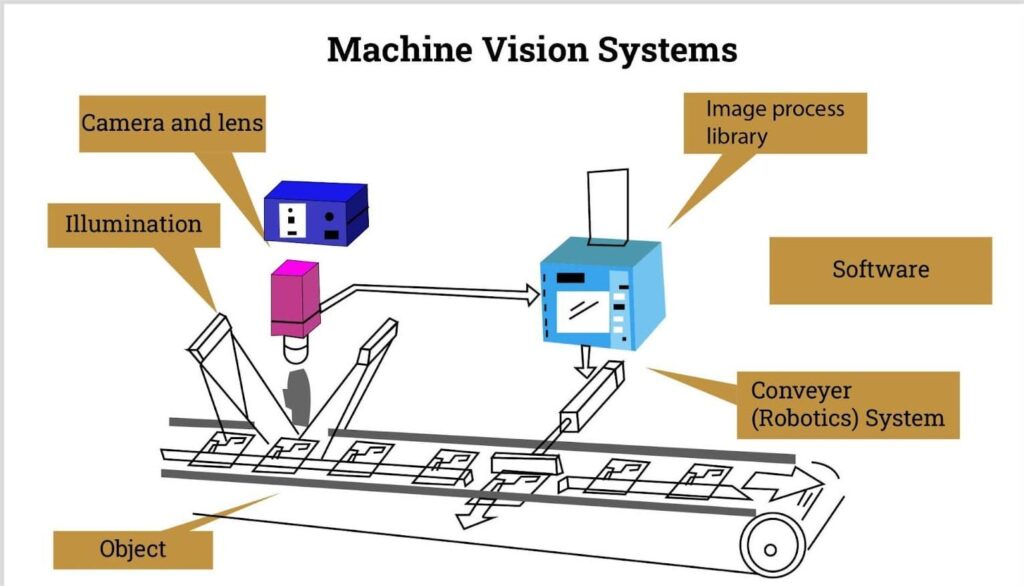

By integrating vision and robotics, our inspection systems enable synchronized automation where detection, decision-making, and corrective action occur instantly within the production line. This intelligent coordination eliminates variability, reduces defects, and enhances manufacturing performance across high-speed industrial environments.

As a trusted provider of vision in pune, AIP delivers scalable machine vision solutions designed for modern smart factories that demand accuracy, traceability, and continuous quality monitoring. Our systems are engineered to support Industry 4.0 manufacturing by enabling intelligent inspection, automated data capture, and predictive quality analytics.

Our vision inspection system solutions integrate seamlessly with PLC platforms, robotic automation cells, conveyor systems, MES platforms, and industrial data logging systems to provide complete and synchronized quality inspection automation.

Why Choose AIP for Vision Inspection Systems?

Modern manufacturing depends on fast and reliable visual inspection to maintain product quality and reduce defects. A well-designed inspection system ensures consistent detection performance while overcoming the limitations of manual checks.

AIP provides scalable inspection automation supported by advanced imaging and robotics. These systems are built to perform in demanding industrial environments where speed, precision, and consistency are essential.

We design intelligent inspection setups that enable real-time monitoring, adaptive detection, and smooth integration with automated production lines. The solutions help manufacturers improve processes through clear production insights and measurable quality data.

Automation Solutions

Machine Vision Technologies We Integrate

2D industrial cameras

3D vision inspection systems

Smart vision sensors

AI-based defect detection

Deep learning algorithms

Industrial LED lighting systems

Edge computing platforms

Each component is designed to provide stable imaging, accurate detection, and fast processing performance.

Types of Vision Inspection Applications

Surface defect detection

Dimensional measurement inspection

Presence and absence verification

OCR and barcode inspection

Label and packaging validation

PCB inspection

Bottle and cap inspection systems

These solutions support complex inspection tasks where accuracy, speed, and consistency are critical for production success.

AI-Based Quality Control & Analytics

Our AI-driven inspection platforms combine intelligent image processing with robotics integration to deliver adaptive detection, automated pattern recognition, and real-time analytics across the production line. By learning from visual data and process variations, the system continuously refines inspection parameters to maintain consistent performance even as products, materials, or operating conditions change.

Advanced algorithms evaluate images at high speed, identifying defects, deviations, and anomalies with precision while minimizing unnecessary rejections. The platforms monitor production data in real time, enabling faster decision-making, early issue identification, and more stable quality outcomes across batches.

Through continuous data analysis, manufacturers gain clear visibility into process behavior, defect patterns, and performance trends. This enables predictive quality management, automated reporting, and more informed operational planning. With scalable deployment and seamless integration into existing workflows, AIP delivers inspection solutions that elevate quality control from a routine task into a strategic driver of efficiency, reliability, and long-term production excellence.

Industries We Serve

Automotive Manufacturing

Electronics & PCB Production

Pharmaceutical Packaging

Food & Beverage Processing

Medical Device Manufacturing

Industrial Equipment Manufacturing

Our inspection solutions are built to meet strict quality standards across industries.

Benefits of Vision Inspection Systems

100% automated inspection accuracy

Reduced human error and variability

Real-time defect detection and response

Improved compliance and traceability

Faster production cycle validation

Data-driven quality improvement

Seamless integration of vision and robotics

High-performance inspection systems help manufacturers maintain consistent quality while improving operational efficiency and reliability.

FAQs

What is a machine vision inspection system?

A vision inspection system is an intelligent automation solution that uses industrial cameras, AI algorithms, and vision and robotics integration to automatically detect defects, verify dimensions, and ensure consistent product quality.

How accurate are AI-based vision systems?

Modern AI-powered inspection solutions used in vision in pune manufacturing environments can achieve inspection accuracy above 99%, depending on application conditions and system configuration.

Can vision inspection integrate with robotics?

Yes. Our solutions combine vision and robotics technologies to enable vision-guided pick-and-place operations, automated rejection handling, and intelligent production control.

How long does it take to implement a vision inspection system?

Implementation time depends on application complexity, integration requirements, and production environment. Modern no-code and low-code platforms significantly reduce deployment and commissioning time.