MES vs ERP vs SCADA: Choosing the Right System for Smart Manufacturing

For many manufacturers, smart manufacturing software can be confusing.

The debate around MES vs ERP vs SCADA often creates uncertainty about where to invest first.

Although all three systems are essential, they address different layers of factory operations.

Clarity on their purpose is the key to making the right digitalization decisions and building a future-ready factory.

A Simple Analogy: Your Factory as a Human Body

-

- ERP (The Brain): Handles high-level planning, strategy, and resources. Manages finances, inventory, customer orders, and production targets.

-

- MES (The Nervous System): Connects the brain’s plan to the factory floor. Manages real-time execution, ensures the right product is built at the right time with the right materials.

-

- SCADA (The Eyes and Ears): Monitors machines and physical processes. Collects real-time data on performance, temperature, speed, and errors, providing instant feedback to the rest of the system.

What Each System Does Best

1. Manufacturing Execution System (MES): The Factory Floor Manager

MES bridges your business plan (ERP) with actual production. It manages the “how” of manufacturing, including:

-

- Tracking Production in Real-Time: Know where each order is on the production line

-

- Managing Quality: Ensure products meet specifications and maintain product genealogy

-

- Analyzing Downtime: Identify reasons for machine stoppages to improve Overall Equipment Effectiveness (OEE)

-

- Guiding Operators: Provide digital work instructions and track operator performance

2. ERP (Enterprise Resource Planning): The Business Strategist

ERP focuses on the business side, helping plan and manage resources effectively. Its main functions include:

-

- Production Planning & Scheduling: Decide what to produce, in what quantity, and when

-

- Inventory & Supply Chain Management: Track raw materials and finished goods

-

- Financial & Cost Control: Manage budgets, costs, and profitability

-

- Customer Order Management: Handle order entry, fulfillment, and delivery

3. SCADA (Supervisory Control and Data Acquisition): The Machine Monitor

SCADA ensures real-time control and monitoring of the factory floor, focusing on:

-

- Machine & Process Monitoring: Provide live visibility of operations

-

- Alarm Management: Alert staff immediately when issues occur

-

- Data Acquisition: Collect real-time data from PLCs, sensors, and equipment

-

- Process Visualization & Control: Central dashboard to monitor and manage operations

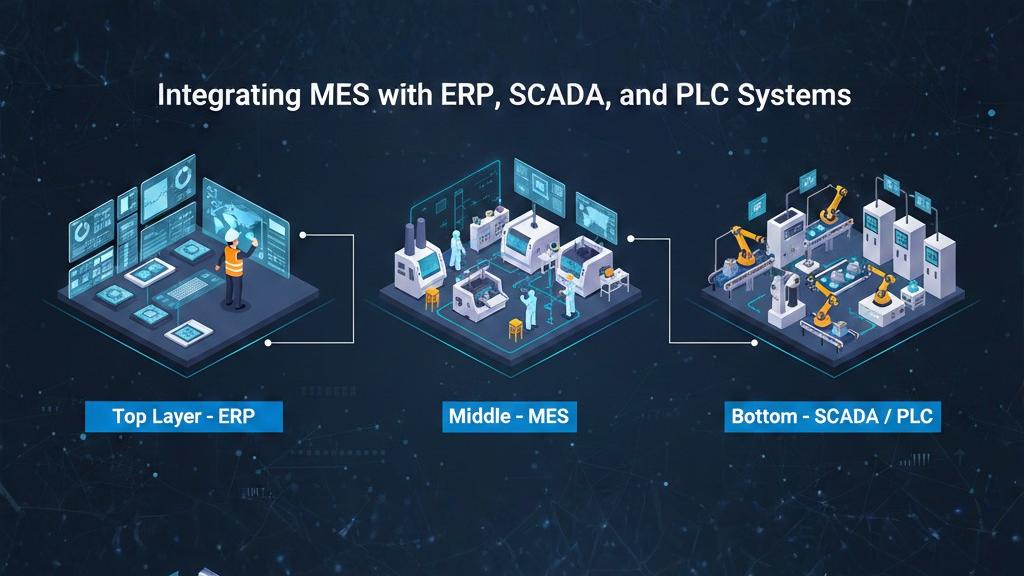

How They Work Together in a Smart Factory

The true value of ERP, MES, and SCADA becomes evident when these systems operate together as an integrated ecosystem rather than in isolation. In the context of smart manufacturing, this integration is what transforms traditional factories into connected, data-driven operations.

ERP (Enterprise Resource Planning), often referred to as the brain of the factory, is responsible for high-level decision-making. It creates production orders based on business planning, customer demand, inventory availability, financial constraints, and resource allocation. ERP ensures that manufacturing operations are aligned with broader business objectives.

MES (Manufacturing Execution System) functions as the nervous system, forming the critical bridge between business planning and shop-floor execution. It receives production orders from ERP and converts them into detailed, actionable instructions for machines and operators. Through real-time tracking of work orders, materials, quality parameters, and production progress, MES ensures that the right products are manufactured at the right time, in the right quantity, and with the correct materials.

SCADA (Supervisory Control and Data Acquisition) serves as the eyes and ears of the factory. Operating at the machine level, SCADA continuously monitors equipment, sensors, PLCs, and industrial processes in real time. It collects vital performance data such as machine status, cycle times, alarms, and energy usage, and feeds this information back to the MES for immediate visibility and control.

When MES vs ERP vs SCADA work in harmony, data flows seamlessly from the shop floor to the top floor and back again. This continuous feedback loop enables faster decision-making, higher operational efficiency, improved transparency, and rapid adaptability to changing production conditions. Together, ERP, MES, and SCADA form the foundation of a fully digitalized, intelligent, and future-ready smart manufacturing environment.

Conclusion: It’s Not “Vs.”, It’s “And”

MES, ERP, and SCADA are not competitors—they are complementary systems that build a resilient and efficient manufacturing operation.

By understanding their unique roles and integrating them effectively, you can create a powerful digital ecosystem that accelerates factory digitalization, boosts productivity, and ensures long-term success in the age of Industry 4.0.