Manufacturing Execution System (MES): Driving Smart Manufacturing in India

Data-driven decision-making and operational excellence are the keys to success in the modern industry, and the MES manufacturing execution system software has emerged as a game-changer for businesses in Pune and India. At Automators Industrial Projects (AIP), we understand MES’s critical role in filling the gap between the ground level and top-level management, enabling seamless communication and real-time visibility into manufacturing operations.

How Are Manufacturing Execution Systems (MES) The Backbone of Smart Factories?

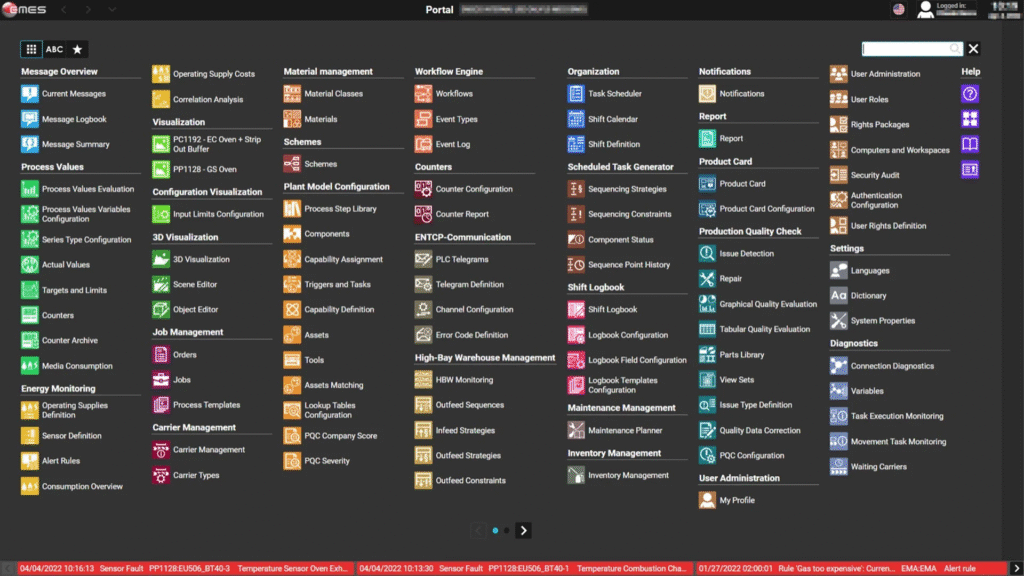

The MES manufacturing execution system software is like the brains of a smart factory. It links people, tools, and processes into a single digital environment. By receiving and processing real-time data from tools, sensors, and business systems, MES software provides valuable insights into production performance, quality management, and resource utilization.

At AIP, we offer a flexible MES software solution that is made to fit the needs of each client in Pune and across India. Our manufacturing execution system software works seamlessly with other systems and connects all production levels, from the shop floor to the corporate level, both horizontally and vertically.

How Do Manufacturing Execution Systems Optimize Processes and Boosting Productivity?

AIP’s manufacturing execution system software is designed to streamline and optimize complex manufacturing processes, empowering businesses to achieve unprecedented productivity and efficiency. With our MES software, companies can:

- Reduce scrap rates and minimize waste through real-time monitoring and quality control measures.

- Increase machine availability by identifying and addressing potential downtimes proactively.

- Detects process deviations early, enabling timely interventions and corrective actions.

- Ensure traceability of production units, enhancing product quality and compliance.

- Leverage real-time visualization and reporting for data-driven decision-making.

- Identify and optimize energy consumption through advanced energy monitoring capabilities.

- Reduce planning efforts and enhance resource allocation with detailed production planning tools.

By leveraging the power of MES software, businesses in Pune and across India can unlock new levels of operational excellence, driving continuous improvement and maintaining a competitive edge in the global marketplace.

How Can Your Business Start Smart Manufacturing With AIP?

At AIP, we understand businesses’ challenges when embarking on digital transformation. That’s why we have developed a comprehensive manufacturing execution system software that can be integrated quickly and easily, enabling companies to start reaping the benefits of intelligent manufacturing in just a few days.

Our modular approach ensures seamless integration and scalability, allowing businesses to expand their MES software capabilities as their needs evolve. With AIP as your trusted partner, you can monitor and optimize production virtually, empowering your employees to utilize raw materials and energy more efficiently.

How Is AIP Driving Innovation with MES Across India?

AIP’s commitment to excellence extends beyond our state-of-the-art MES software solutions. To drive innovation through joint projects, we actively collaborate with clients from diverse sectors, including automotive, medical technology, aerospace, manufacturing, mechanical and plant engineering, precision mechanics/optics, and metal industries.

By leveraging our talents and cutting-edge technologies, we have helped numerous businesses in Pune and across India increase their productivity on the shop floor by up to 20 percent, fostering a culture of continuous improvement and sustainable growth.

Final Words

FAQs (Frequently Asked Questions)

What are the key features of a modern MES?

Modern MES solutions include real-time monitoring, digital work instructions, quality management, predictive maintenance, and integration with IIoT (Industrial Internet of Things).

How does MES help with regulatory compliance?

MES maintains detailed digital records of production data, which helps manufacturers comply with industry standards like ISO, FDA, and GMP by providing accurate audit trails.

Can MES improve workforce productivity?

Yes, MES provides operators with real-time instructions, alerts, and performance tracking, reducing errors and increasing workforce efficiency.

How does MES support predictive maintenance?

MES integrates with sensors and machine data to predict potential equipment failures, minimizing downtime and improving asset lifespan.

Is MES suitable for small and medium-sized manufacturers?

Absolutely. Modern cloud-based MES solutions are scalable and cost-effective, making them ideal for SMEs looking to digitize their operations.

What role does MES play in Industry 4.0?

MES acts as the digital backbone of Industry 4.0 by enabling smart factories, machine-to-machine communication, and data-driven decision-making.

How secure is an MES solution?

MES systems follow strict cybersecurity protocols, including encrypted communication, access controls, and regular updates to protect sensitive production data.