PLC SCADA HMI Development & Commissioning

At AIP, we specialize in PLC SCADA HMI Development, delivering advanced automation solutions that enhance efficiency, speed, and operational control. Our expertise in PLC SCADA HMI Development is strengthened by modern No-Code and Low-Code platforms, enabling faster deployment and reduced dependency on specialized programming skills. As a trusted PLC SCADA automation company, we provide reliable PLC programming services for automotive, process, and factory automation applications. Backed by years of industry experience, our PLC SCADA HMI Development solutions help manufacturers achieve measurable improvements in productivity, system visibility, and scalability.

Why Choose AIP for PLC SCADA HMI Development?

The industrial automation landscape is evolving rapidly, increasing the demand for advanced PLC SCADA HMI Development solutions that are faster, more reliable, and easier to scale. As systems grow more complex, manufacturers require efficient PLC programming services, robust SCADA software development, and intuitive HMI interfaces. AIP meets these demands through a modular and intelligent PLC SCADA HMI Development approach designed for modern factories.

Our proprietary automation frameworks, automated tools, and extensive libraries of pre-tested function blocks significantly reduce development time. Instead of starting from scratch, engineers can focus on system optimization and customization. As an experienced PLC SCADA automation company, AIP delivers structured PLC SCADA HMI Development solutions that improve consistency, reduce errors, and accelerate project delivery.

Automation Solutions

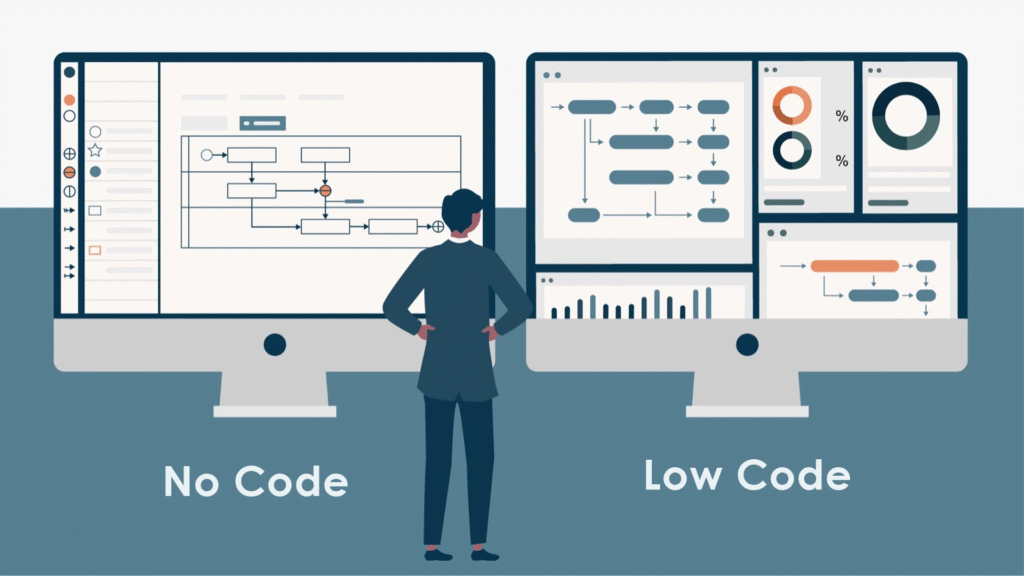

No Code, Low Code Approach to Modern PLC SCADA HMI Development

Time is the most valuable resource in industrial automation. That’s why AIP’s No Code, Low Code framework for PLC SCADA HMI development is transforming the way automation projects are delivered. Whether it’s a greenfield installation or modernization of legacy systems, our approach significantly reduces development time while minimizing dependency on complex manual coding.

Our PLC SCADA HMI development solution streamlines workflows using pre-validated templates and intelligent auto-code generation, ensuring faster execution and consistent quality. This enables:

Faster time to market

Reduced programming errors

Smooth collaboration between engineering teams

By replacing traditional programming with intuitive configuration, AIP makes PLC SCADA HMI development more scalable, easier to maintain, and faster to deploy—helping manufacturers achieve agility without compromising reliability.

Virtual Commissioning: Reducing Time and Risk

AIP’s PLC SCADA HMI Development solutions leverage advanced virtual commissioning to simulate real-world industrial environments before actual deployment. This cutting-edge approach can reduce commissioning time by up to 90%, helping businesses accelerate operations while minimizing unexpected downtime.

Through digital simulation of machines, devices, and control logic, our engineers can test and validate systems safely and efficiently. By combining our PLC programming services with expert PLC SCADA automation company capabilities, we ensure seamless collaboration between design and commissioning teams, maintain strict safety compliance, and fast-track your system’s go-live schedule.

Advanced SCADA Software Development

We elevate PLC SCADA HMI Development to the next level. Our PLC Tool Generator streamlines tag creation and seamlessly connects SCADA layers to PLC programs, eliminating manual errors and saving valuable time. Tags are automatically populated from predefined PLC configurations, ensuring accuracy and efficiency.

Our solutions also provide:

-

Real-time monitoring and alarms

-

Historical data trending and logging

-

Customizable dashboards and reports

-

Multi-user access with role-based control

Whether you’re building from scratch or revamping an existing HMI, our team ensures that operator panels are intuitive, responsive, and aligned with international usability standards..

Dynamic and Intuitive HMI Development

AIP offers seamless HMI development tailored to user experience and functionality. Our library of pre-built, standardized icons, widgets, and screens reduces design time without compromising customization.

We support development across platforms such as:

Siemens WinCC

Schneider Vijeo

Rockwell FactoryTalk

Mitsubishi GT Designer

GE Cimplicity

Whether you’re building from scratch or revamping an existing HMI, our team ensures that operator panels are intuitive, responsive, and aligned with international usability standards..

Custom Report Generation & 3D Visualization

Beyond basic functionality, our systems bring intelligence to your dashboards. Generate multiple customized reports effortlessly using our smart templates. Whether you need batch reports, performance summaries, or maintenance logs, everything is available in real time.

We also integrate 3D visualization tools for projects that require spatial clarity and interactive interfaces. From digital twins to system layouts, this functionality enhances operator understanding and supports effective decision-making.

Industries We Serve

Our solutions are engineered for high performance across a wide range of industries:

Automotive Manufacturing

Food & Beverage

Water & Wastewater

Pharmaceuticals

HVAC and Building Automation

Power and Energy

Special-Purpose Machines.

Partner with AIP: Redefining Automation Systems

At AIP, we’re not just solution providers—we are innovation partners. With our combination of expertise in PLC programming, modern SCADA software, and intuitive HMI development, we help our clients realize the full potential of their automation infrastructure.

Join us as we redefine the way automation projects are delivered. Contact AIP today to discover how we can streamline your next PLC SCADA HMI project from concept to commissioning.

FAQs

What is PLC SCADA HMI development?

PLC, SCADA & HMI development refers to designing, programming, and commissioning automation systems using Programmable Logic Controllers (PLC), Supervisory Control and Data Acquisition (SCADA) systems, and Human-Machine Interface (HMI) panels. These systems work together to control and monitor industrial processes.

How does AIP ensure rapid PLC SCADA HMI development?

AIP uses No Code/Low Code platforms and an extensive library of pre-tested modules, reducing development and commissioning time by up to 90%.

What industries benefit from SCADA software and HMI development?

Industries like automotive, manufacturing, pharmaceuticals, and food processing benefit greatly from reliable SCADA software and customized HMI development for efficient operations.

Can AIP customize PLC programming for OEM standards?

Yes, AIP has expertise in programming PLCs for OEMs using standards like Integra and TMO, tailored for brands like Daimler, BMW, VW, and Navistar.

What makes virtual commissioning essential?

Virtual commissioning allows AIP to simulate system behavior before physical deployment, reducing errors, saving time, and ensuring smooth implementation.