Manufacturing Execution System-MES

In today’s highly competitive manufacturing environment, real-time visibility and process control are essential for operational excellence. A robust Manufacturing Execution System (MES) acts as the digital backbone of modern factories, connecting shop-floor operations with enterprise systems to enable smarter, faster decision-making.

At Automators Industrial Projects (AIP), we design and deploy advanced MES software for automotive plants that supports production tracking, quality management, and compliance with OEM and industry standards. Our solutions are built to handle the complexity of automotive manufacturing while ensuring scalability, reliability, and seamless system integration.

Through flexible industrial MES solutions, AIP supports manufacturers across the entire MES lifecycle—from requirement analysis and system design to implementation, validation, and optimization. Our structured approach ensures improved productivity, enhanced traceability, and a smooth transition toward smart and sustainable manufacturing.

Why Choose AIP for Manufacturing Execution System MES Solutions?

At Automators Industrial Projects (AIP), we deliver more than just technology—we provide impactful Manufacturing Execution System (MES) solutions designed to solve real-world manufacturing challenges. Our approach combines industry expertise, practical implementation, and scalable architecture, which is why manufacturers across multiple sectors trust AIP as their MES partner.

With proven experience across automotive, aerospace, and precision engineering industries, we have successfully deployed Manufacturing Execution System (MES) platforms that improve production visibility, quality control, and compliance. Our specialized MES software for automotive plants is built to handle complex workflows, traceability requirements, and OEM standards with ease.

We offer complete lifecycle support, guiding manufacturers from initial consulting and system design through deployment, training, and ongoing optimization. Our industrial MES solutions are modular and scalable, allowing businesses to start small and expand seamlessly toward a fully connected smart factory.

Thanks to our streamlined deployment methodology, manufacturers begin seeing operational improvements in days rather than months. By transforming real-time shop-floor data into actionable insights, our MES platforms enable data-driven decision-making that boosts productivity, reduces costs, and supports long-term digital transformation.

Automation Solutions

Why Smart Manufacturing Needs an Advanced MES

The transformation into a smart factory begins with creating a cohesive digital environment. Our Manufacturing Execution System MES offers real-time visibility and control, streamlining operations and bridging the gap between planning and execution.

- Connect Machines Digitally

Create a cohesive digital network by integrating all machines on your shop floor. Real-time data acquisition helps you optimize performance, detect inefficiencies, and predict potential issues before they impact production.

- Visualize Operations with Reporting Tools

With powerful visualization dashboards, track performance metrics across departments. Generate actionable insights to make data-driven decisions that enhance output and reduce waste.

- Integrated Energy Monitoring

Track energy consumption in real time using our MES platform. Gain insights into high-consumption equipment, apply energy-saving strategies, and contribute to your organization’s sustainability targets.

- Full Lifecycle Track and Trace

Ensure traceability across every production stage. Our MES solutions strengthen quality control, enable instant feedback, and comply with industry regulations for traceability and documentation.

- Detailed Production Planning

Leverage intelligent scheduling to allocate resources efficiently, reduce lead times, and achieve greater production flexibility. Our MES system makes production planning smarter and leaner.

- Streamlined Document Control

Digitize and centralize document management for seamless operations. Ensure real-time updates, version control, and secure access to critical documentation from anywhere.

Sustainability with MES: CO2 Neutrality and Near-Zero Factory

Going green is no longer just an option. Our Manufacturing Execution System MES supports initiatives to achieve CO2 neutrality. By optimizing energy use, minimizing material waste, and digitizing processes, we help you aim for a near-zero factory footprint.

Paperless Factory Operations

Eliminate paper trails. Go fully digital with workflows, documentations, approvals, and reporting. This improves response times, reduces errors, and supports an eco-friendly production model.

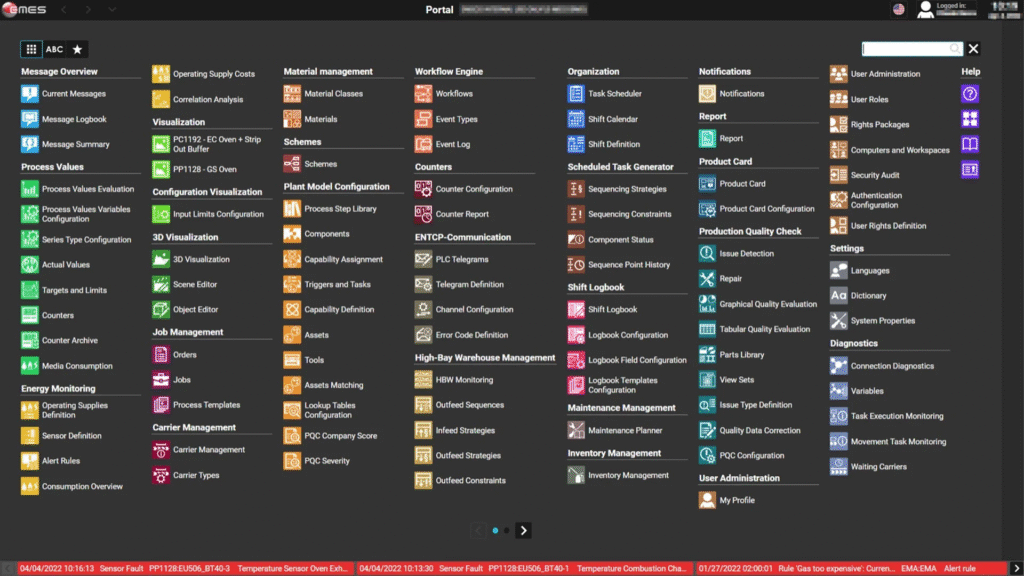

Modular MES Solutions for Digital Manufacturing

At AIP, we offer a modular MES platform designed for seamless digital transformation. From heterogeneous machine connectivity to data acquisition (MDA/PDA), OEE analysis, traceability, and predictive maintenance, our MES makes smart manufacturing a reality.

- Machine Data Acquisition (MDA) and Production Data Acquisition (PDA)

- Performance analysis and real-time efficiency metrics (OEE)

- Traceability for every unit and batch

- Planning, scheduling, and document control in one place

Real-Time MES Integration Across IT Levels

Our MES solutions form the backbone of modern manufacturing by integrating systems both horizontally across departments and vertically between production and enterprise systems. Get real-time sync with ERP systems and monitor machine health, setup times, and downtime in one unified dashboard.

- Machine status & availability updates

- Downtime reason codes and quantity tracking

- ERP-level integration for production orders and reporting

- Real-time analytics for performance and quality

Industry Success with MES Implementation

Whether you’re in the Automotive, Aerospace, Medical Technology, Metalworking, or Plant Engineering sectors, our Manufacturing Execution System MES has helped clients improve production output by up to 20% through joint innovation projects.

Our clients benefit from:

- Reduced scrap rates and material waste

- Early detection of process deviations

- Increased machine availability

- Shortened planning cycles

Start Your MES Journey with AIP

You don’t have to wait months for digital transformation. With our plug-and-play MES modules, your factory can achieve digital visibility and efficiency in just a few days. Our systems are designed for quick setup, minimum downtime, and maximum impact.

Join us in transforming your factory into a high-performance smart factory with our advanced Manufacturing Execution System MES. Let’s connect to discuss the best MES solution for your production goals.

FAQs

What is a Manufacturing Execution System MES?

A Manufacturing Execution System (MES) is software that connects, monitors, and controls manufacturing processes on the shop floor. It provides real-time visibility and control over production operations, ensuring improved efficiency, traceability, and productivity.

How does MES improve factory performance?

MES solutions improve performance by providing real-time data for decision-making, reducing downtime, increasing machine utilization, and streamlining workflows across departments. It bridges the gap between ERP systems and plant-floor operations.

Can MES be integrated with existing systems like ERP?

Yes, modern Manufacturing Execution System MES platforms are designed to integrate seamlessly with ERP, SCADA, and IoT systems to ensure full digital connectivity and operational transparency.

What industries benefit the most from MES implementation?

Industries such as automotive, aerospace, electronics, pharmaceuticals, metal fabrication, and food processing significantly benefit from MES solutions due to the need for precision, traceability, and efficiency in production.

Is AIP’s MES solution customizable?

Absolutely. AIP provides modular and customizable MES solutions that adapt to your factory’s unique workflows, machines, and reporting needs. Whether you need energy monitoring, real-time visualization, or predictive analytics, AIP has a solution.

How long does it take to implement AIP's MES?

With AIP’s plug-and-play approach, MES implementation can begin delivering value within just a few days. Full deployment timelines depend on factory size and complexity, but rapid configuration is a core benefit.

Does AIP’s MES support CO2 neutrality and sustainability goals?

Yes. AIP’s Manufacturing Execution System MES includes features like energy monitoring, paperless documentation, and waste tracking, helping factories move toward CO2 neutrality and environmentally sustainable production.

What makes AIP’s MES different from other MES solutions?

AIP’s MES is built with a modular, scalable, and quick-to-deploy architecture. It supports horizontal and vertical integration, offers real-time analytics, and helps achieve up to 20% productivity improvement through data-driven insights.